VERSIFOAM® LATEST NEWS

RHH Foam Systems is a huge fan of Warrior Homesteads, the organization that builds tiny houses for homeless veterans. Their mission is to give homeless veterans sustainable housing in self-sustaining communities.

The Cincinnati-based nonprofit uses VersiFoam® spray foam kits to insulate the homes they build. In order to meet the huge need for homes, Warrior Homesteads is consulting with a company in Cincinnati to build a trade academy called “R Academy”. The vision for R Academy is that it will be an all-inclusive school that provides room, board, and education at no cost to the students. Once the students are trained, they will have the skills to be hired by for-profit employers.

Founder Glenn Grootegoed says, “I am working on developing a curriculum to teach the students how to build tiny homes which would then become affordable or emergency housing.” The home that was built to develop the curriculum is called the Hummingbird XL. It will be given to a farming homestead in upstate New York that’s owned by a minority, female veteran.

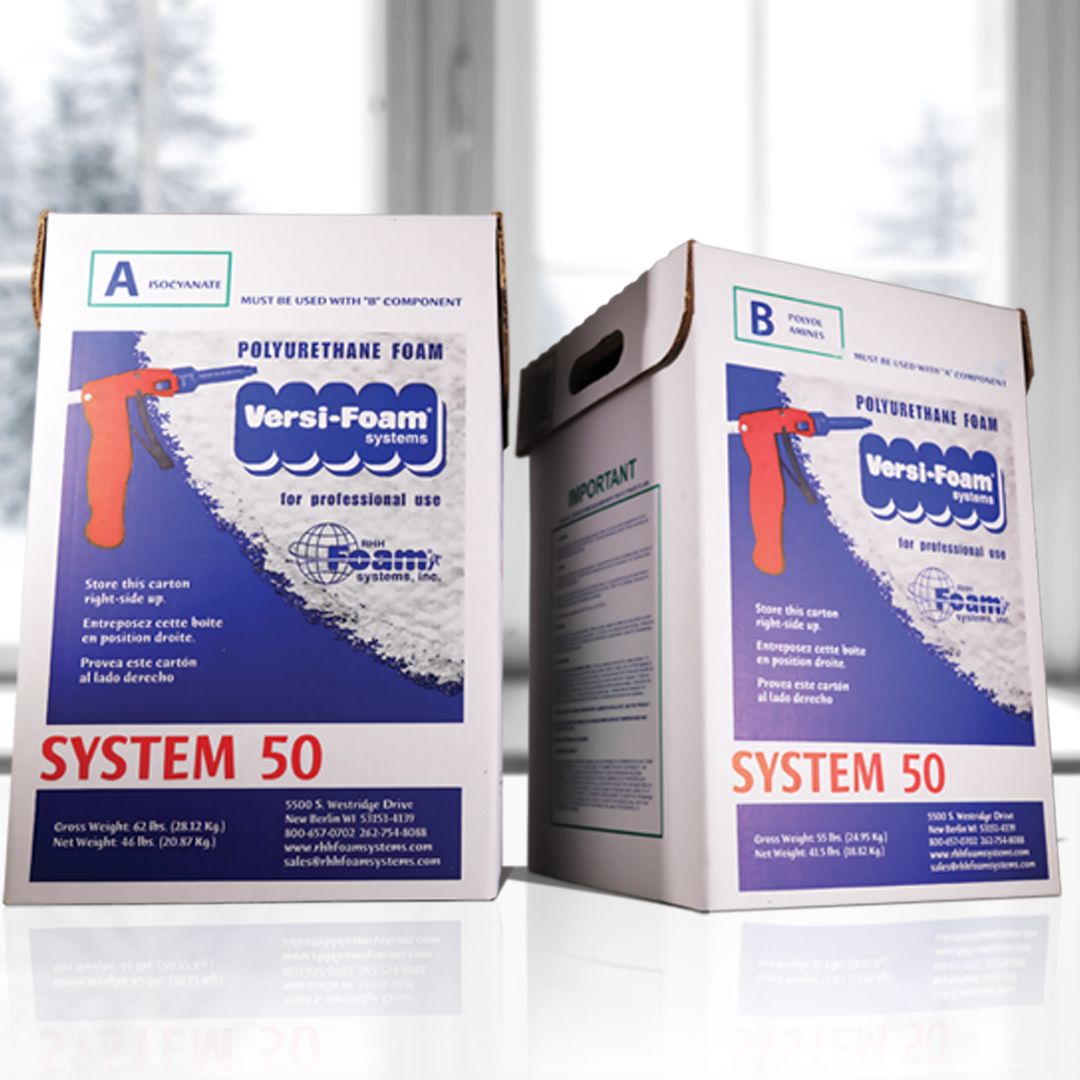

Warrior Homesteads will teach students how to insulate a foundation in a tiny house using the System 50 kits, which are just the right size to complete the project.

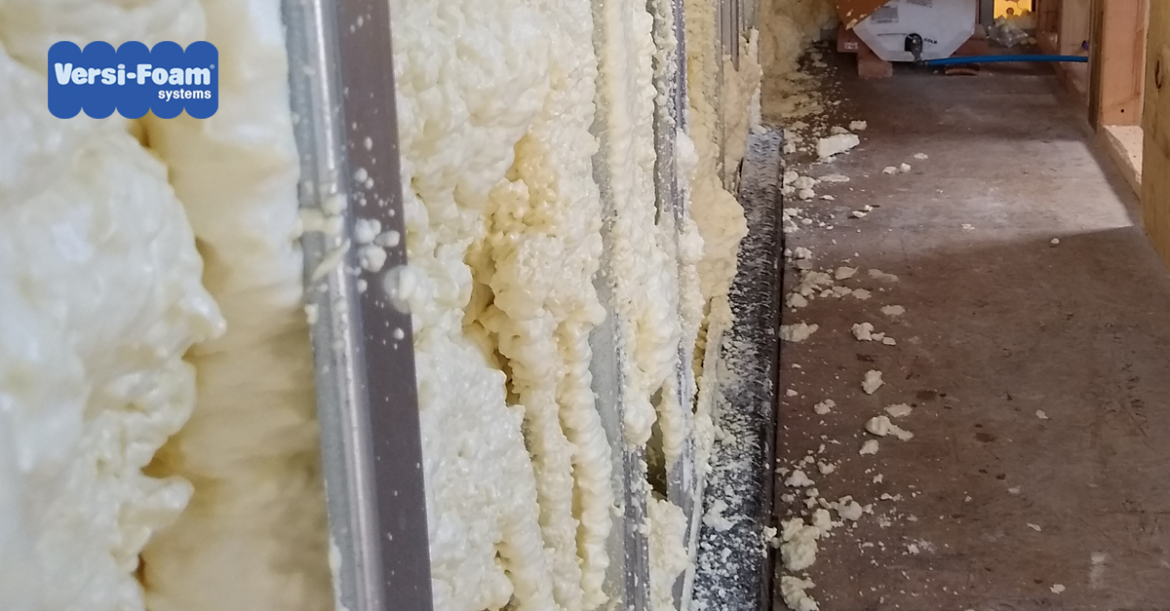

The videos below give you a behind-the-scenes look into tiny home insulation and the beginnings of R Academy. Watch just how quickly and easily the Hummingbird XL can be insulated.

About half of the average household’s energy budget goes to heating and cooling. This is a cost that you as a consumer have direct control over. You already know you can turn down your thermostat a few degrees in winter and up a few degrees in summer. But did you know that’s not all you can do to save energy costs? In fact, you don’t need to adjust your thermostat to uncomfortable levels to save money. Using the proper insulation will accomplish the same goal.

Deciding which type of insulation to install is often described as a balance of cost and performance. Choosing a lower initial cost means that the total cost of ownership will be spread out over the installation’s lifetime, i.e., every month in the form of higher ongoing energy costs.

There are three basic types of home insulation. Cellulose insulation is made of plant fibers and is one of the earliest insulation materials used. Fiberglass is an insulation material primarily composed of extremely fine glass fibers. Spray foam insulation is a spray-applied cellular plastic that’s made by combining chemicals to create foam.

Because spray foam virtually eliminates air infiltration, its insulating effectiveness is higher than either fiberglass or cellulose. Neither fiberglass nor cellulose creates an air seal while spray foam insulation does.

“Other products are insulation only, but spray-foam insulation is air-impermeable, which allows it to be an air barrier as well as insulation,” says Paul Duffy, vice president of engineering at foam manufacturer Icynene, in Mississauga, Ontario. “Typically, what happens with insulation products is that if there’s no air barrier, the thermal performance varies. That could have several consequences—increased heat flow and air leakage that can carry moisture into unwanted places, leading to mold.”

All three types of insulation are easy to install although each type does have its potential gotchas. Cellulose can settle and shift over time if it’s not installed properly. Fiberglass requires great attention to detail as even small gaps can significantly reduce its efficiency and the wall cavities need to be completely filled. While spray foam insulation kits have made installation easy for the average person, the installer does need to read the instructions carefully before beginning and perhaps watch a how-to video.

The location of the insulation is another important consideration. Spray foam is the best choice in moisture-prone areas, like basements, because it isn’t susceptible to mold like fiberglass is. Spray foam insulation, fiberglass, and cellulose are all environmentally friendly. They are each easy to install and safe to use with one small exception for fiberglass, since the fibers can be inhaled or get into the skin, causing irritation.

Spray foam insulation provides several important benefits that fiberglass and cellulose don’t. It dampens sound, protects against insects, and is moisture resistant. Spray foam insulation does initially cost more than either cellulose or fiberglass, but the overall cost is comparable when you consider the air barrier, the water-resistant barrier, and the vapor barrier. It is an added value that will pay itself back over time.

Choose VersiFoam. Find a distributor near you today!

How do you choose the right spray foam insulation kit? If you’re new to the product, it might not look like there are any significant differences between brands, but we can assure you, there are. VersiFoam® was born out of extensive experience in the construction industry. We learned what spray foam insulation users need to complete the job quickly, easily, and successfully.

Reasons to choose VersiFoam® Spray Foam Insulation Kits

Ease of Use. The patented U-Control gun allows you to control how much foam is dispensed by how hard you pull on the trigger. It couldn’t be easier or more intuitive. VersiFoam® kits are also portable and disposable.

The kits also come equipped with a plastic temperature strip which lets you know at a glance whether the foam is at the ideal temperature for use. If the foam is too cold or too hot, the yield will be lowered. If the temperature of the foam is too cold (the indicator on the strip is in the blue area), warm the containers until the indicator moves to the green area. If the foam is too hot (the indicator on the strip is in the red area), cool the containers until foam is in the ideal range.

In addition, most of our systems can be shut down and used on another day, giving you the flexibility you need to get the job done.

No Experience Necessary. If you’ve never used a spray foam insulation kit before, there’s no need to be apprehensive. We’ve taken great care to provide all the information a first-timer needs to be successful. In addition to the easy-to-read temperature indicator and the U-control gun, we’ve provided how-to videos in English and Spanish. There is also a scannable FAQ page on our website with a detailed trouble-shooting guide.

Product Quality. VersiFoam® doesn’t contain any urea formaldehyde, volatile organic compounds, chlorofluorocarbons, or Penta-BDEs. All of our Class I kits are manufactured with an anti-microbial formula that stops mold from growing on the surface of the foam and provides a safeguard against the growth of the five most common types of fungi found in homes.

Product Support. Our friendly, knowledgeable customer support center is available to you if you run into issues or just want to talk to someone before beginning your project. We have made product information and application instructions easy to find on our website, which means you don’t have to hunt for answers to your questions. The dealer locator helps you to quickly find a dealer near you so that you can work on your own timeline.

Flexible and Versatile. Most of our spray foam kits can be shut down and reused again on another day. Only the System 1 kit needs to be used the same day it’s opened. The U-Control gun allows you to dispense foam at a rate low enough to write your name with it or as high as 6 lbs. per minute. VersiFoam® kits can be used by one person or a group of people working on the same project. Once the foam is fully cured it can be sanded, cut, carved, shaved, or painted.

Take a look at our easy, intuitive 9-step application process and visit a dealer near you to talk about your project.

1. Shake each tank or box.

2. Make sure the chemical tanks are within the green operating temperatures.

3. Connect the hoses.

4. Turn the tank valves to the “on” position.

5. Perform a test shot.

6. Attach a nozzle to the dispensing gun.

7. Disengage the safety.

8. Point the gun at your target.

9. Pull back on the trigger.

VersiFoam® is a versatile and portable low-pressure spray foam insulation system. In addition to residential and commercial insulation, it can be used for pool and spa insulation, marine flotation, vehicle insulation, sound dampening, to create an air barrier, and to create props and special effects. Here are some of the things you can do with it.

VersiFoam® can be used to create detailed stage and film props that are only limited by your imagination. It can be used as a sculpting medium and a molding material to create just about anything, in any size. You start by building a base of wood, wire, styrene board, or whatever works best for you. Next, you spray apply the foam to the base, layering and building it up to create the form you’ve designed. Then, allow it to cure. You can now mold it, carve it, sand it, cut it, grind it, shave it, paint it, and coat it. You can create any surface texture in any shape and color.

VersiFoam® is one of the easiest closed cell foam kits to use for marine flotation. Closed cell foam spray is ideal to use for buoyancy in boats. It is less susceptible than most other products to moisture intrusion. In case of leakage, closed cell foam absorbs less water than open cell foam. Our kits meet U.S. Coast Guard specifications for marine flotation.

VersiFoam® provides superior insulation for vehicles such as trucks, vans, RVs, and buses. Most refrigerated trucks, trailers, and vans have polyurethane foam in the walls, ceiling and floors to provide insulation for temperature control. Repairs are simplified using VersiFoam disposable foam kits because they don’t require a separate power or pressure source. Because the flow of chemical is controlled by the pull of the trigger, hard to reach areas and tights spots are easily insulated using VersiFoam.

VersiFoam® is an outstanding insulator for pools and spas. Most pool and spa owners use a cover to help maintain water temperature. However, they may downplay the importance of spray foam to help prevent heat loss on the sides and bottoms of their pool or hot tub. A minimum 2″ thickness of medium density polyurethane spray foam on the shell will provide sufficient insulation. If the manufacturer has not provided at least 2″ of foam, you can supplement the existing foam to meet this minimum requirement. One System 15 kit is enough foam to cover two 300 gallon shells with 2″ of foam.

VersiFoam® open cell spray foam is a cost effective, efficient way to dampen sound. It creates a barrier which absorbs noise, inhibits the transfer of sound between rooms and reduces noise that enters the building from the outside. The spray foam works because sound is airborne and the foam reduces the air space through which the sound can travel.

VersiFoam®contributes to a better performing building envelope by completely sealing gaps and crevices. This prevents air infiltration, moisture infiltration, and the intrusion of dirt and pollutants from the outdoors. The air barrier system of spray foam insulation is a critically important element for economic control of heat transfer. An inadequate barrier system will allow leakage of air through holes, leaks, cracks and gaps which allows heat to flow through the structure.

VersiFoam® has a high R-value, extreme moisture tolerance, and low permeance. It is portable, doesn’t need a power source, and can be used in tight spaces. It is both versatile and easy. All you do is gear up, hook up, and spray. How will you use the versatility of VersiFoam® on your next project?

If you’re new to spray foam insulation kits, knowing which product to buy might be confusing. At RHH Foam Systems, we are always happy to spend time on the phone with you talking through your project. But if you want to get up-to-speed quickly on your own, here is a quick start guide to choosing the right VersiFoam® product.

Are you insulating a place that will be inhabited? Inhabited spaces include homes and commercial buildings where people come to work on a daily basis. Inhabited buildings need to be insulated with a Class 1 Formula closed cell spray foam. This formula is flame retardant accordance with ASTM E-84 and will limit flame spread and smoke development if exposed to a fire. All of our closed cell spray foam products are available in the Class 1 Formula. As an added bonus, all of our Class I kits are manufactured with an antimicrobial formula that stops mold from growing on the surface of the foam. This added element provides a safeguard against the growth of the five most common types of fungi found in buildings.

How dense do you want your spray foam insulation to be? VersiFoam’s density ranges from .75 lbs per cubic foot in our open cell spray foam to 2.8 lbs per cubic foot in our high density closed cell spray foam. High density foam is used when you need extra strength for load support, roofing, or exterior applications. Lower density open cell spray foam is more flexible and will adjust itself as your structure settles over time. Standard density spray foam (1.75 lbs per cubic foot) is the most commonly used and will be the best choice for your project if you don’t need either high flexibility or high strength.

What is the size of the space you need to insulate? You want to factor in both square feet and the thickness of your application in inches. Plan to apply 3-4 inches in roof decks and 2-3 inches in the walls. Once you have this information, go to our Spray Foam Insulation Calculator and enter it. It will tell you how many kits you should purchase for each system.

Are you trying to achieve a certain level of energy efficiency in your office space or home? The primary measurement of energy efficiency is R-value which is the capacity of an insulating material to resist heat flow. A higher R-value equals higher resistance to conduction heat transfer.

Do you need to spread your work over several days? All of our spray foam kits can be shut down and used on another day except for the System 1 closed cell formula. It’s designed for smaller projects and needs to be used on the same day that it’s opened.

Are you insulating your personal property? VersiFoam® is an excellent insulator of RVs, buses, trucks, and vans. It’s often used to insulate the sides and bottoms of pools and hot tubs and is very popular for marine flotation as well. If you need the foam to be able to flow into a cavity before solidifying, then consider using the slow rise foam insulation which becomes tack-free in about 3 minutes instead of 30-45 seconds.

We hope this short guide helps you to find the product you need quickly. We also provide detailed instructions on our how-to page and a complete video library in English and Spanish here. If you still have questions about selecting the right spray foam insulation kit, please call us at 1.800.657.0702. We would love to hear from you.

Depending on where you live in the United States, winter may be right around the corner or several weeks away. The feeling of winter doesn’t depend on the actual temperature—it depends on how well you’re acclimated to a temperature range. When it hits 45 degrees in Florida in December, locals are cranking up the heat, making tea, and digging out their down jackets. In Wisconsin, we are finally starting to admit that winter is coming.

If you care about your pocketbook, when it’s time to turn on the heater, you want it to do its job quickly and efficiently. Money spent on warm air escaping into the attic or seeping out of windows is money you can’t spend on something that really matters to you. With VersiFoam® spray foam insulation, you can have the best of both worlds—insulation the pros use at a price you can afford. Keeping your welfare and warmth in mind, here is your step-by-step guide to a well-insulated winter.

The VersiFoam® Warm Winter Checklist

Doors and windows

The frames around windows and doors provide an easy way for warm air to escape out of the house and for cold air to elbow its way in. This is one of the easiest air leaks to fix and we recommend starting your inspection there. Stand close to your windows and notice if there is a temperature difference between that area and the center of the room. Move the palm of your hand around the door frame to see if air from the outside is seeping in. If it is, Versi-Tite® is our one-component sealant designed specifically for small gaps and openings. It dispenses as a caulking bead and can be used around door and window framing.

Attics

An uninsulated attic is a money pit so most attics have some type of air barrier. However, it is still worth a few minutes of your time to go up and check the quality of the insulation. If it’s been several years since the attic was insulated, the insulation material may not be the most efficient or may have deteriorated over time. While you’re up there, check for holes in the ceiling and open spaces around chimneys, exhaust fans, and plumbing installations. These can be sealed easily with one of our spray foam insulation kits. You will also need a 15-minute ignition barrier for fire protection.

Cathedral ceilings

Rooms with cathedral ceilings can be notoriously uncomfortable in winter as the warm air rises above where people spend their time. If most of that warmth escapes through the ceiling, you can run your furnace all day without noticing much difference. If you have a cathedral ceiling, check to see if the area between the roof deck and the rafter is insulated. If it’s not, once you insulate those cavities, you’ll notice the difference in the comfort level of your home.

Basements and crawl spaces

The first thing to do in your basement or crawl space is to check the area where the walls meet the foundation. Houses settle over time and cracks appear that need to be sealed. Next, examine the openings where the electrical, plumbing, and heating services enter the house. This is one of the quickest and easiest insulation jobs to perform yourself. Our video library will show you how.

HVAC systems

Check both your HVAC unit and your duct system. Even the most expertly designed system will lose heat if it’s not properly insulated. Expanding polyurethane foam is an excellent and easy way to seal space between the HVAC system and your walls, ceilings, and floors. Air infiltration and duct leakage put a large burden on your furnace. Our disposable foam kits can be used in tight spaces without outside sources of power or pressure.

VersiFoam® is an expandable foam that prevents cold air infiltration by sealing gaps and crevices air-tight. For more information about VersiFoam® residential applications, visit our website!

Are tiny houses a solution to veteran homelessness? Glenn Grootegoed of Warrior Homesteads thinks so and he has been working to show it can be done since 2014. Warrior Homesteads builds tiny homes and works with veteran’s organizations to house homeless vets.

In 2018, the estimated number of veterans experiencing homelessnes in the U.S. was almost 38,000. (Source: HUD) According to the National Coalition for Homeless Veterans, “The most effective programs for homeless and at-risk veterans are community-based, nonprofit, ‘veterans helping veterans’ groups. Programs that seem to work best feature transitional housing with the camaraderie of living in structured, substance-free environments with fellow veterans who are succeeding at bettering themselves.”

The Kroger Veterans Association Resource Group knows this because earlier this year, they approached Warrior Homesteads with an offer to work with them to build a tiny house for a deserving veteran in the Cincinnati area. The home needed to be ready for their annual “Honoring Our Heroes” 5K Run/Walk. VersiFoam was honored to be a small part of that effort by providing the spray foam used for the insulation of the new house.

On June 15, 2019, before the start of the 5K, a local homeless veteran was given the tiny home. It was equipped with high-quality, eco-friendly appliances. The house contained a kitchen, bathroom, full-sized bed, and storage space. And it was well insulated.

The Warrior Homestead Facebook page on May 20th said, “Thanks to our friends at VersiFoam it’s insulation day!!!!! We are working on the 2019 Kroger Honoring Our Heroes Festival and 5K tiny house project. We are huge fans of VersiFoam, as it’s simply the best!” And we are huge fans of Warrior Homesteads.

Here are some pics from the day…